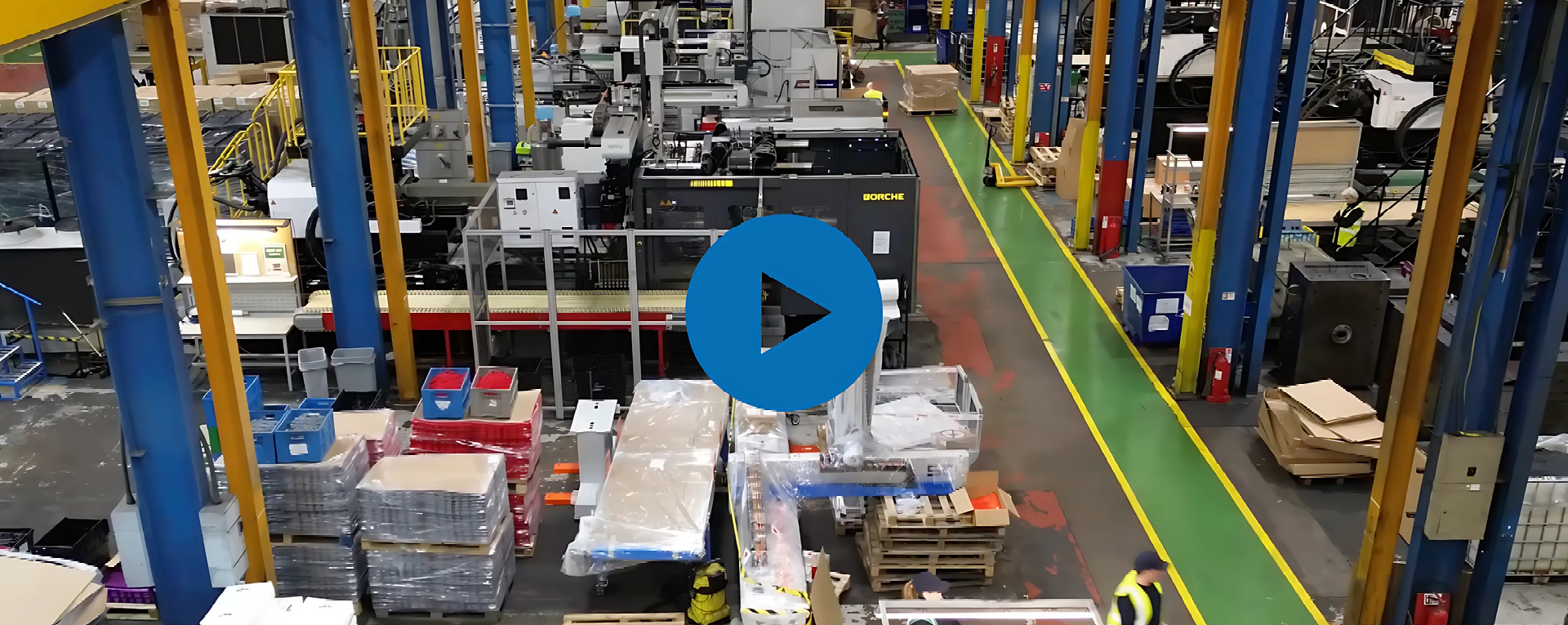

Plastic Injection Moulding UK

High-Performance, Precision Injection Moulding Services For Durable, Custom Components

Boost production capacity, support new product development, streamline product assembly or seamlessly move existing tools while ensuring high-quality, durable components and efficient processes.

Plastic Injection Moulding Solutions UK

Struggling With Costly & Slow Productions?

Inconsistent quality, slow production and high costs can limit your success. Precision injection moulding is fast, cost-effective and reliable, helping you scale without compromise.

Plastic Injection Moulding Benefits

Delivering injection moulding processes designed to offer efficiency, precision and cost savings for your business. Backed by state-of-the-art equipment, delivering reliable solutions to meet your unique needs.

Fast Turnaround Times

Streamlined services without compromising on quality.

High Precision & Quality

Meticulous attention to detail and stringent quality control.

Scalable Production Capacity

From small-batch prototypes to large-scale production runs.

Cost-Effective Solutions

Competitive priced products to help you maximise your ROI.

Custom Design Capabilities

Tailored to you, from material selection to intricate design.

State-of-the-Art Equipment

Producing high-quality, complex parts with consistent precision.

We started using Ravensbourn about three years ago. Since then, we've had a stress-free and seamless experience disposing and buying plastic. The staff at Ravensbourn are professional, knowledgable and efficient. No need to look elsewhere.

Oliver Bennett

Managing Director

Injection Moulding Materials We Offer

We provide high-quality moulding materials designed to meet the diverse needs of your projects with precision, durability and reliability.

PP Virgin

PP Recycled

HDPE Virgin

HDPE Recycled

Nylon

GFN (50%)

Expert Design & Tooling For Injection Moulding

Trust in technical plastic injection moulding experts designing to ensure your project is one of innovation and excellence.

Custom Design Solutions

Develop tailored designs to meet your exact specifications, ensuring your parts are designed for optimal functionality and efficiency to achieve the highest-quality end product.

Precision Tooling

Utilise state-of-the-art technology to create high-quality, durable moulds and tooling, to ensure perfect replication and consistency across large-scale production runs.

Prototyping & Iteration

Refine your product before entering full-scale production, prototype designs allow you to test, refine and perfect designs to ensure the final product meets all expectations.

Material Selection

Expertise in selecting the best materials for both design and tooling to ensure that the final product is durable, cost-effective, flexible and sustainable.

3D Printing Solutions For Injection Moulded Products

3D printing allows for rapid prototyping and design validation to test and refine your product before hitting go on full-scale production, in turn saving you time and reducing costs.

End-To-End Project Management For Seamless Execution

We are committed to providing a seamless injection moulding process from initial concept through to full-scale production.

Dedicated Project Managers

Connect with a dedicated project manager who oversees the entire process, ensuring a tailored service.

Transparent Milestone Tracking

Stay in the loop with every stage of the project with clear milestones and regular progress reports.

Risk Management & Mitigation

Our proactive approach to identifying and addressing potential risks ensures that your project stays on track.

Plastic Injection Moulding FAQs

Got a question about injection moulding? Our experienced team are here to help.

What materials can be used in injection moulding?

A wide range of thermoplastics can be used, including HDPE (High-Density Polyethylene) and PP (Polypropylene), which offer durability, flexibility and chemical resistance for various applications.

Is injection moulding suitable for large-scale production?

Yes, injection moulding is highly scalable, making it ideal for both small-batch prototypes and large-scale production runs. Its ability to produce consistent, high-quality parts makes it a preferred choice for mass manufacturing.

How environmentally friendly is injection moulding?

Modern injection moulding machines use energy-efficient technology to reduce power consumption, and the process itself generates minimal waste. Additionally, many plastics used can be recycled, helping to lower environmental impact.

Do you deliver injection moulded products?

We offer two options for delivery: we can deliver your order directly to you, or you can choose to pick it up from our manufacturing plant. Please arrange your preferred option at the time of placing your order.

I can't find what i'm looking for, can you help?

If you can’t find what you’re looking for, don’t worry! Please get in touch with us and let our experienced team at Ravensbourn help you find the right product for your needs.

Our Injection Moulding Process

We pride ourselves on delivering clear guidance through every stage of the injection moulding process. From initial consultation to final delivery we ensure precision, efficiency and high-quality results at every step.

01

Initial Consultation

An in-depth consultation ensuring we fully understand your objectives, key requirements and desired outcomes.

02

Design & Prototyping

Collaborating closely to create precise designs and prototypes to visualise and refine your product.

03

Tooling & Mould Creation

Develop custom tooling and moulds required to manufacture products using advanced technology.

04

Injection Moulding Production

With moulds in place, the injection moulding process begins producing durable components with accuracy.

05

Quality Control & Testing

Products undergo rigorous quality control and testing to ensure it meets the highest-standards and defect free.

06

Delivery & After-Support

Timely delivery of components and on-going post-production support, modifications and assistance.

Advancing Circular Economy Solutions Across the UK & Europe

Through innovative and responsible manufacturing, we foster a closed-loop system that continually repurposes resources, ensuring sustainability at every stage.

Where We Operate

- United Kingdom

- Germany

- Belgium

- Holland

- France

- Spain

- Denmark

- Poland

- Norway

- Sweden

- Finland

Work With Our Friendly Team

Ready to experience the difference in high-quality, custom HDPE and PP plastics? Whether you are wanting to sell, buy or need specialised designs, reliable toll services, or premium materials, Ravensbourn is here to help.

© 2024 All Rights Reserved | Ravensbourn Limited. Reg. No. 1447928 |

Privacy Policy